The Pile Pusher Pro makes optimum use of existing Cone Penetration Testing technology to, while pushing piles into the soil, collect crucial data for reliable confirmation of soil data from Cone Penetration Tests performed beforehand. Why does the data-driven side of installing foundations make all the difference in the construction industry of 2020?

As an electronic engineer, Erik Landskroon, Data Acquisition Specialist at A.P. Van Den Berg, is closely involved in data acquisition by Cone Penetration Testing (CPT) equipment. “The new pushing technique produces a great deal of data analysis on things such as the foundation machine’s pushing force, which offers countless opportunities for reliable foundations.”

Mechanical Cone Penetration Testing

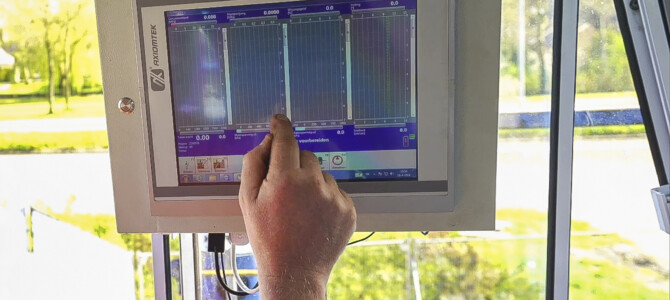

The Pile Pusher Pro was initially imported from China into the Netherlands as a bare foundation machine to which A.P. Van Den Berg Geotechnology B.V. could add its own twist. “We installed measuring equipment and a depth registration device on the machine to pave the way for the collection of measuring data. This made it possible to build extremely reliable foundations. We specialise in Cone Penetration Testing technology, and we have applied this specialist knowledge to this foundation machine. You measure the same kind of parameters. It basically makes the Pile Pusher Pro more than just a piling system, as it becomes an extremely large version of a mechanical Cone Penetration Testing system,” says Erik.

Reliable foundation pile positioning

Is this data analysis method actually still necessary when you are already building the foundation? Erik: “The hydraulic pressure we use to push each pile foundation into the soil is measured. And we convert this data into a total force. This gives us a graph that is the same as that produced by mechanical Cone Penetration Testing to determine soil resistivity. The data can then be compared to data from cone penetration tests performed prior to the project. The data recorded thus also provides valuable input for calculations of each pile’s actual load-bearing capacity. You can then compare this to the original pile plan. It is ultimately a practical test to check that each pile pushed is up to the task and that the design is adequate. This gives us a reliable idea of the positioning of the foundation pile.”

Safe foundation

“The load-carrying capacity graphs produced by the Pile Pusher Pro’s data acquisition system can be used to corroborate the safety level of the foundation constructed and used as input for piles that are yet to be inserted. The design could also be changed as piles are pressed into the soil and new data becomes available, so as to prevent ending up with too many or too few piles and prevent unnecessary construction costs and/or failure costs,” says Erik. Fundamentally better, therefore, for the reliability of the foundation design and the actual foundation.